- Intelligent image processing supports quality control in industrial companies

- With individual feasibility studies for optimal project structure

- HELLA Aglaia advises and accompanies with expert knowledge from two decades

A good three years ago, a HELLA annual report presented a deep-learning project in which AI-based image processing was used to set up efficient and precise quality control for laser welding spots. The project’s backbone: machine learning algorithms made by HELLA Aglaia. This year, the Institute of Plastics Processing at RWTH Aachen University became aware of the project report. An invitation to a symposium on digitalization in the industry followed. At the beginning of November, HELLA and HELLA Aglaia presented a joint insight into the reference project as part of the conference. An occasion for taking a closer look at the topic of automatic optical inspection (AOI).

From the road to production

For more than two decades, HELLA Aglaia has dedicated itself to computer-aided image evaluation and has made a name for itself, particularly in the automotive sector: High-precision detection algorithms evaluate images from the vehicle’s front camera, identify pedestrians, vehicles or traffic signs, among other things, and transmit information about them to the control system. The control system can trigger an appropriate reaction, for example, adapting the vehicle’s speed to a detected traffic sign.

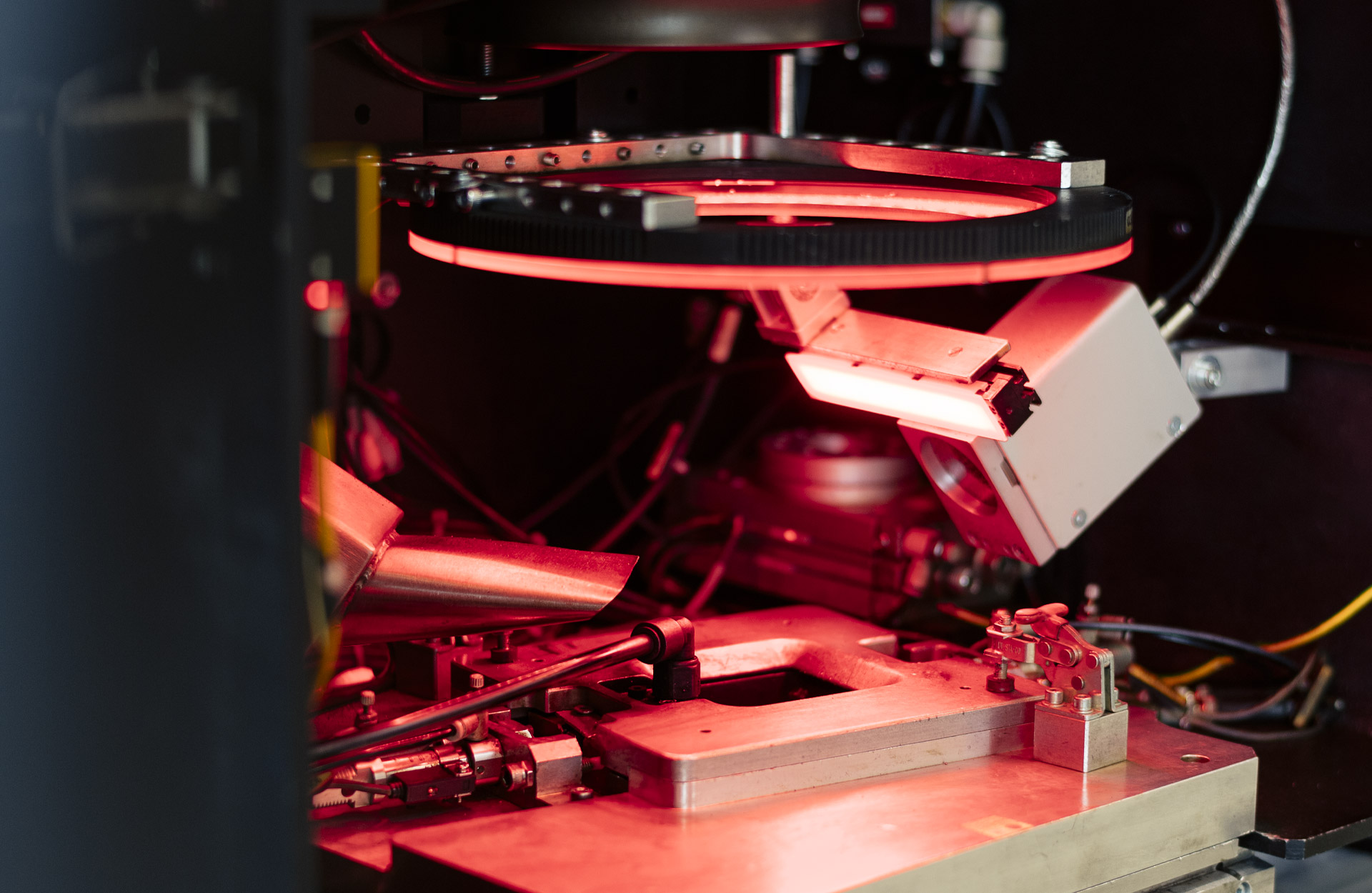

The principle can be transferred to numerous other areas, including automatic optical inspection in production processes. At the end of a production process, the products are recorded by a camera. Next, algorithms examine the image material for previously learned defined features that can be used to detect anomalies in the surface, for example. The detection results are sent back to the end of the production process – in real time. As part of a quality control process, defective products can be automatically sorted out or designated for rework.

Deep learning as a key to success

The implementation of this inspection is made possible, among other things, by the application of deep learning algorithms, a sub-area of machine learning. In contrast to classical optical inspection systems, features do not have to be firmly defined by the software engineer, but instead are created independently on the basis of patterns contained in large amounts of sample data. This is made possible by neural networks, a form of self-learning algorithms. The more comprehensively the neural networks are trained to the relevant properties of a pattern, the more precise the detection results will be. Quality control thus benefits from the reliable, consistent classification of the examined objects.

Consulting and implementation from one source

Whether and how a project can be supported by means of deep learning is examined in advance by the specialists at HELLA Aglaia with extensive feasibility studies. If the imaging procedure has not been specified yet, various camera and illumination scenarios are tested in the in-house optics laboratory in order to find the optimal imaging setup for solving the respective task.

How an image template is generated is ultimately irrelevant for the algorithms. A thermal imaging camera was used for the reference project of laser welding spots; other projects work with classic RGB cameras or X-ray images, depending on the material to be examined and the objective of the test. Our team will be happy to assist you with any questions or requests for advice. For more information on automatic optical inspection, please visit our AI Solutions product page.